Journey to SaiSure Nutritions LLP – Mr. Susheel Kumar, Project and Process Consultant, SaiSure Nutritions, LLP

This article describes the personal journey of Mr. Susheel, who was chosen by Sadguru Sri Madhusudan Sai to be the instrument for overseeing and setting up the SaiSure Nutritions plant, thereby starting a manufacturing facility that would cater to the needs of material supply of Annapoorna Trust. This article gives you an insider’s view of what happened and how it happened!

The genesis of SaiSure Nutritions LLP (SSNLLP)

It was in early October 2020 when a common associate, who happens to be an ardent devotee of Sadguru Sri Madhusudan Sai, contacted me in Mysore and informed me about the philanthropist work that Annapoorna Trust, Muddenahalli is doing to provide Morning Nutrition through breakfast and SaiSure health supplement to school-going children of Karnataka state in collaboration with the State Government – Ksheera Bhagya project.

At that time, the health supplements for pregnant women, toddler, and preschool and school children were outsourced by SaiSure from renowned food processing companies in and around Bengaluru. The SaiSure, think tank, in one of our meetings at Bengaluru, expressed their interest in setting up the plant to manufacture different variants of SaiSure and informed that a special purpose vehicle in the form of SaiSure Nutritions LLP (SSNLLP) has been registered with the Company Law Board.

Since January 2020, SSNLLP representatives were in correspondence with many equipment providers for setting up the plant and had gone around to many manufacturing units, including Amul, Gujarat, to see their facilities for selecting the process and equipment. Many alternatives were being examined for the plant – ranging from setting up the extrusion cooking to drum dryer and roasting plant entailing huge investment.

In December 2020, SSNLLP requested me to get involved with them as a consultant to set up the health supplement plant. Since I come from a very different background of project experience in setting up Alcoholic Beverage Plants, I had apprehension about accepting the assignment, and whether I could do justice to meeting the expectations of the stakeholders.

A strong resolve to set up the plant

However, my first visit to Sri Satya Sai Ashram in January 2021 changed my perspective after going around and seeing the vast campus with multiple activities encompassing education institutions with 1500 children, all in boarding facilities from 6th to 12th standard, functional hospital for Pediatric congenital heart surgery and distribution of breakfast & Health Nutrition supplement – all free-of-cost. I felt it was some divine blessing that I have been identified for being part of this great mission of selfless love and service. The resolve became stronger.

Having accepted the assignment, the first task was exactly to define the process and capacity of the plant and build a strong project team who would later take up the responsibility of operating the plant. Again, I would say that the people identified by our beloved Sadguru Sri Madhusudan Sai for the project were as if they had been in the Ashram for the very same purpose and were eagerly waiting for that day.

Planning of technical specifications

Data published by the Women and Child Development Department of Karnataka State provided us with all the beneficiaries – district-wise, under each category of pregnant women, toddlers, and preschool & school children aged 6 yrs. and above. We relied on this data and decided to have a processing plant to meet the requirement of 2 million beneficiaries covering 10 districts under these 4 categories. Considering a serving size of 10-15g per day per beneficiary, a plant of capacity 500 Tons/mo. was envisaged.

Since the total area available for setting up of the plant was 12,900 sq ft, we planned to go vertical to create space for storing Raw Materials and Finished products, Process area, Utilities like- DG, Electrical substation, Air Compressor, Water treatment plant, Laboratory, and Administrative area.

Many processes flow, starting from Pneumatic conveying, Extrusion Cooking for Millet to drum dried products, were examined and discussed with many reputed OEMs for supply of equipment starting from Andritz India, Buhler India, Reico, and Knitcon Pune. Reputed manufacturing units were visited, engaging in the production of Health supplements for third parties and their own brands as well, such as Griffith Evexia, Parsons, PMV Malt, Bar Malt, Milkose, etc. Some of these companies are associated with MNCs like Mondelez for Bourn Vita, Danone for ProteinX, and Hindustan Unilever for Horlicks and Boost.

Since Extruded Multi-millet product was needed as one of the ingredients in Pregnant Women and Toddler and the quantity needed was not warranting to set up an Extrusion Cooking plant which is a highly capital and Energy Intensive unit, it was decided to outsource extruded Multi-millets to SSNLLP for the formulations.

Annapoorna Trust realized that SaiSure – chocolate formulation with mineral and vitamin fortification—had made the reconstituted Whole Milk Powder, provided to the school children by the state government under the Bhagya Shree project, acceptable, and school children were relishing the fortified drink.

Therefore, it was felt in unison that the product formulation for school children needs to be malt based on chocolate formulation. Besides providing micro nutrition to the school children, it also improved their self-esteem as they were drinking chocolate products like Boost and Bourn Vita, which only the elite could afford.

Since the malt extract is highly hygroscopic and needs a controlled atmosphere to process, it was decided to have dehumidified air at a low RH of 45% and 26 *C.

Project Management

Having finalized the capacity of the plant, the Process Flow, Product Mix, Formulations, and Ingredients, initiated the introduction of Project Management to plan, control, secure and organize resources to attain the specific objective as early as April 2021.

All possible techniques and aspects of Project management, namely Project Initiation, Project Planning, and Project Execution, were introduced to track the progress of the project and achieve timely Project closure with MS Project -Gantt Chart and timelines.

The project implementation core team with defined roles and responsibilities was ready by March 21st. We had a Project Manager to oversee construction and plant erection & installation, a Manager to work on state Project clearances, HR, and Quality Assurance, and a team for interacting with vendors, financials, and Lending Institutions.

The Architect for drawing the plant layout and the Electrical consultant for finalizing the external and internal electrical installation was appointed on April 21 as part of the core team.

A detailed project report – (DPR) document with Financials was prepared in-house in April 2021 to approach the lending Institutions for Term loans to meet the Capex requirement and have the financial closure with promoters’ equity. The same DPR in an abridged version was made ready for submission to various Govt. Departments – like KSPCB, BESCOM, Director of Factories and Boilers, Office of the Asst. Labor Commissioner, FSSAI & Department of Fire and Safety for approvals and Licenses.

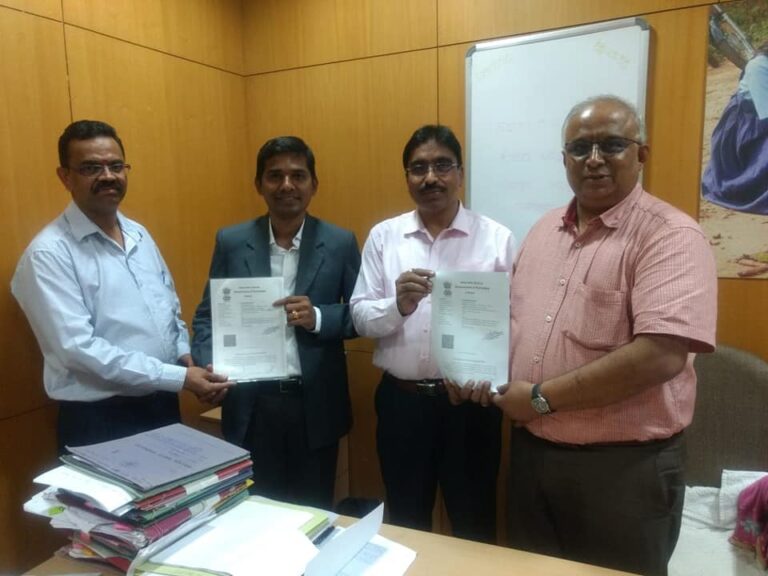

By Oct-21, the State Bank of India approved the term loan, and the amount was ready for disbursement as advance along with the PO to various vendors for the supply of process equipment and Utilities.

Vendor Assessment and Evaluation

Although the vendor assessment process was challenging, the team was effective in finding low-risk sources for high-quality equipment and services. By Nov.21 – Dec.21, vendor assessment for the supply of major equipment to meet the technical specifications of the plant and organizational standard and obligations once under contract were finalized by introducing the technical Bid Analysis process in four stages-

- Preliminary Evaluation,

- Compliance with technical requirement,

- Price evaluation and

- Due Diligence

By Jan.22-Feb.22, the major vendors were finalized, and the letters of Interest were issued with proper Purchase orders and agreed advance amounts, with deliveries of Plant & machineries by Oct.22.

The civil work, after finalizing the flow diagram and process P & ID through a process of vendor assessment and Technical Bid analysis, was finalized on Feb.22.

The major Vendors are-

- Knitcon Solutions Pvt Ltd, Pune—the Process Plants

- BryAir and Green Leap—Dehumidifier and HVAC

- Vanishri Constructions—Civil and Structural work

Civil work begins

It was indeed a momentous day at SaiSure Nutritions LLP, Muddenahalli, when the civil work was started on 6th March 22. The total built-up area is 24000 sq ft with a 6-storeyed process building. The process area is provided with pharmaceutical-grade Ucrete flooring.

Each process floor is provided with air ducts with filters for the inflow of clean, conditioned air of low RH of 45% and Temp. 26*C

SSNLLP is a state-of-the-art nutraceutical manufacturing facility with material flow from the top down to the ground floor for packing in laminates and pet jars, which makes it energy efficient.

The Compliance team could get the CFE from KSPCB well in time and power sanction from BESCOM and approval from the Director of Factories and Boilers, while the FSSAI approval was pending.

The Gantt Chart drawn on 6th March suggested 21st December 2022 as the day for Pre-commissioning of the plant, but due to unforeseen situations, the erection of equipment which should have started on October 22, got delayed and was started on 5th December 2022.

The major challenge has been the inadequate infrastructure for engineering and workshop in Muddenahalli, and for any store and spares & engineering support, the unit needed to depend on resources from Bengaluru.

Inauguration of SaiSure Nutritions LLP

The manufacturing facility of SaiSure Nutritions LLP, Muddenahalli, was inaugurated on a very auspicious day by Sadguru Sri Madhusudan Sai on 14th January 2023, and the commercial production commenced on 22nd Feb.2023, exactly 4 years after the conceived idea as guided by Sadguru Sri Madhusudan Sai on 22nd Feb 2019, when the official launch of SaiSure was announced in the presence of the former Hon. Chief Minister of Karnataka – Sri Kumaraswamy ji.

Thereafter, the unit has produced 35 tons of Ragi formulation in March 2023 for the State of Telangana and is now poised for 120 tons of production for the State of Telangana in May 2023. Our beloved Swami has envisioned 5 such plants in rural areas of the State of Karnataka in the next 10 years and hopefully in many other states where Annapoorna Trust has introduced the health supplement to address “Hidden Hunger.” The job is not completed until Sadguru Sri Madhusudan Sai’s mission of “Let No Child Go to School Hungry Ever” is accomplished.